It is time for engineer's day where top 20 projects, inter-section challenge, robotic challenge are compete with each other. Here we would like to grateful to all who help us direct or indirectly in making this project successfully done. special thanks to our supervisor Mdm. Nulida Bt. Abd Aziz which help and give full support on us and the project. Finally with all the effort, our project are nominees on 2nd place for innovation challenge. Not to forget our decorator adviser, Nurfaezah Talib who help us on the giving the idea on how to decorate our project which indirectly become the reason why our project wins.

Thursday, 26 April 2012

Tuesday, 24 April 2012

WEEK 14

Thursday, 19 April 2012

WEEK 13

Design a poster by using Microsoft Power Point. In the designed poster, we have attached some important information as stated in the guideline for the poster format in the RPS. The information include, Objective, methodology, application, results, block diagram, description, and reference.

|

| Poster : Adaptive Street Lighting System |

Thursday, 12 April 2012

WEEK 12

We have encountered a major problem, where our PCB does not working. This is maybe because of our PCB layout design got some error that we cannot trace. We have designed another PCB for the 2nd time but then still encountered the same problem. After a long unsolved troubleshooting period, we decided to use our test board for the main controller circuit that control the system which is a working circuit when we tested before.

|

| Test Board for the project |

Wednesday, 4 April 2012

WEEK 11

This is one of a difficult part to do in this project because there are many tools and component need to use and also we need to make the wiring for every each of the lamp we have. All of the wiring for the light pole is combine it by using a connector.

|

|

|

| The wiring for the each light pole that being set on the model |

|

| It is how the model looks a like |

Friday, 30 March 2012

WEEK 10

Finding all the part of Adaptive Street Lighting System model for the FYP presentation and competition. These are the main parts of this Adaptive Street Lighting System.

|

| Plywood |

This plywood is used as a base for this model to make it more reliable and not easy to bend and damage the model.

|

| Polystyrene |

Polystyrene is attach before the Black Mounting board is attach. It is used for making wiring path.

|

| Black Mounting Board |

Black Mounting board is act like a street in this model.

|

| White Tape |

So this White Tape will be the road lines for this model.

| Adjustable wall lamp |

This type of wall lamp will be the light pole for the project.

Tuesday, 27 March 2012

WEEK 9

After develop the PCB board, the component's holes being drilled and the component being assemble on the board.

Wednesday, 21 March 2012

WEEK 8

Make a Printed Circuit Board (PCB) for a change to our project bread board. It will be more simpler, more orderly, and smaller size. Here is the process of making a PCB by using BMI PCB workshop.

|

| Printed Circuit Board (PCB) |

A printed circuit board, or PCB, is used to mechanically support and electrically connect electronic components using conductive pathways, tracks or signal traces etched from copper sheets laminated onto a non-conductive substrate.

|

| UV Exposure Box |

|

| UV Exposure Box |

UV light is exposed to the presensitized copper clad boards. The transparency blocks traces that you want to leave on the board. When the board is immersed in the developer solution, the green enamel is dissolved away wherever light was exposed. Then, wherever there is no enamel and just copper.

|

| PCB Salt |

This PCB Salt is used to dissolved the copper at board.

|

| PCB Etching Machine |

This is the process where to clear all the cooper on top of the board and only left a cooper that we printed before.

Thursday, 15 March 2012

WEEK 7

Thursday, 8 March 2012

WEEK 6

|

| LDR and Controller circuit being construct on BreadBoard |

The circuit being constructed on breadboard for testing and troubleshooting methods.

The LDR circuit function as we expected.

The controller circuit did not work after the construction being made. We continue to troubleshooting the circuit by referring to the connection between the components. After several days, we found that the value of the ceramic capacitor did not work for the design. We change the capacitor with another value of it which is before this we used 1nF and we change it to 33pF. The circuit functioning as we needed.

Saturday, 3 March 2012

WEEK 5

Went to Jalan Pasar to buy the components for the 3 main circuit which is controller, light sensor, power supply circuits.

Friday, 24 February 2012

WEEK 4

Programming for the system to function as we expected.

The programming shown as follow:

#include <16F877A.H>

#fuses NOWDT,HS, NOPUT,NOPROTECT

#use delay (clock=20000000)

#define PUSH_BUTTON PIN_D0

#define PUSH_BUTTON1 PIN_D1

#define PUSH_BUTTON2 PIN_D2

void main ()

{

int x=1,y=1,z=1;

int count=0;

while(TRUE)

{

output_a(count);

x=input(PIN_D0);

y=input(PIN_D1);

z=input(PIN_D2);

if(x==0)

{

output_b(0b00011111);

if(y==0)

{

count++;

delay_ms(300);

output_a(count);

output_b(0b00011111);

output_c(0b00000001);

delay_ms(1000);

output_c(0b00000011);

delay_ms(1000);

output_c(0b00000111);

delay_ms(1000);

output_c(0b00001111);

delay_ms(1000);

output_c(0b00011111);

delay_ms(1000);

}

else if(z==0)

{

count--;

delay_ms(300);

output_a(count);

output_b(0b00011111);

output_c(0b00011111);

delay_ms(1000);

output_c(0b00011110);

delay_ms(1000);

output_c(0b00011100);

delay_ms(1000);

output_c(0b00011000);

delay_ms(1000);

output_c(0b00010000);

delay_ms(1000);

output_c(0b00000000);

delay_ms(1000);

}

}

else

output_b(0b00000000);

}

}

Thursday, 16 February 2012

WEEK 3

R&D on the street lighting module that cover it's bulb, distance between street light poles.

It will help us on how to reduce the scale of the project by following what is the exact scale of street light.

It will help us on how to reduce the scale of the project by following what is the exact scale of street light.

Tuesday, 7 February 2012

WEEK 2

On second week another briefing held on Gemilang Hall. From this briefing the FYP committee inform that all the thesis submit and claim can be do on week 17.

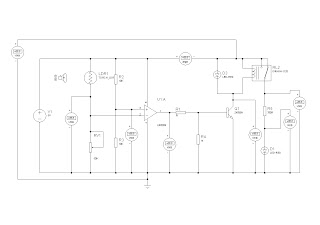

Circuit for LDR sensor and power supply to be approved by supervisor.

Circuit for LDR sensor and power supply to be approved by supervisor.

LDR sensor circuit

Power supply circuit

Friday, 27 January 2012

WEEK 1

Briefing about Final Year Project at Gemilang Hall That be brief by FYP committee about what need to do for this semester.

A meeting with supervisor being held to schedule works and discuss about what to start with.

Subscribe to:

Comments (Atom)